Wood Drying Time Chart

The traditional rule-of-thumb for air-drying lumber is to allow one year of drying time per inch of wood thickness.

Wood drying time chart. METHODS OF WOOD DRYING By Daniel Yourdon Over the past year I have been gathering information on various methods of wood drying. How Can You Tell If The Wood Is Dry Without A. 88 rows Months to Dry.

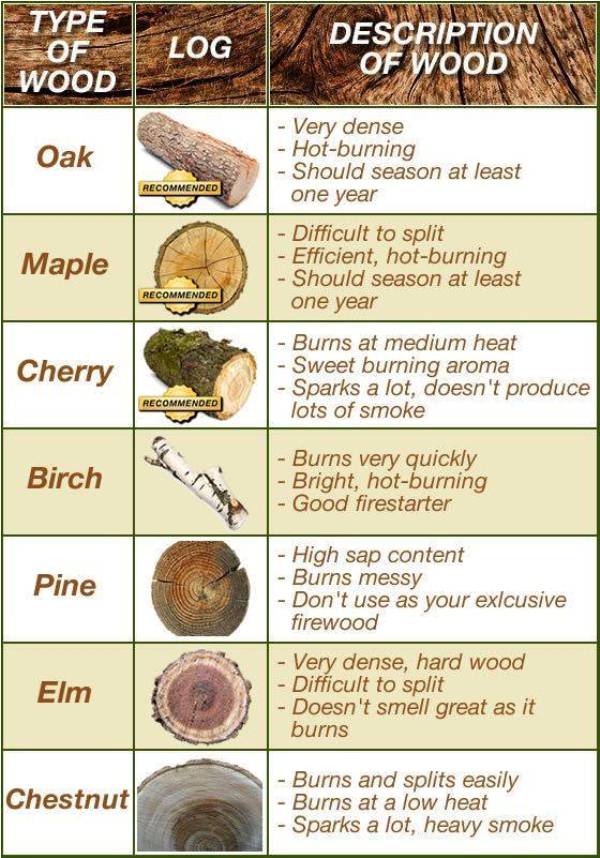

Use the chart below to find your best burning firewoods. Using the Air-Drying Estimator to Predict the Air-Drying Time for Lumber. 3 12 Stevens Rd Brewer ME 04412 The World Leader in Lumber Drying Systems Since 1977 Nyle has been building the worlds most energy efficient lumber dryers.

Some hardwood takes between 1 2 years to season. American elm 104. Well the answer to that question is.

This adage obviously only takes a few of the aforementioned variables into account but its at least a rough starting point in understanding the time investment required in order to properly air-dry lumber. California black oak 2-4. Split wood dries faster because it has more area exposed to the air than full logs with bark.

BOILING Drying time reduced an average of 50 over air-drying A large portion of this information was taken from Comments written by Steven D. Long Medium or Short drying time. Hop Hornbeam Ironwood Ostrya virginiana.

Which is typical for drying wood the reading will correspond to the depth of the tip of the insulated electrodes. Wood Drying Time Chart. 5 5 This should be handed out with each stove purchase from every manufacturer so people understand Great Post.

2-foot pieces a standard firewood length will dry in about six months while 4-footers may take a year. This will let you know whether your wood is ready to use or needs more time to dry. The drying times are based on drying 254cm 44 lumber.

Of this publication is to make available to dry kiln operators and others interested in kiln-drying wood kiln schedules that are completely assembled and written out for ready reference and easy use. Carpet plot after 5 h of drying. Osage Orange Hedge Maclura pomifera.

Let the filler sit for five to twenty minutes. 5 5 I like the drying time chart too. The constant or ovendry weight and the weight of the.

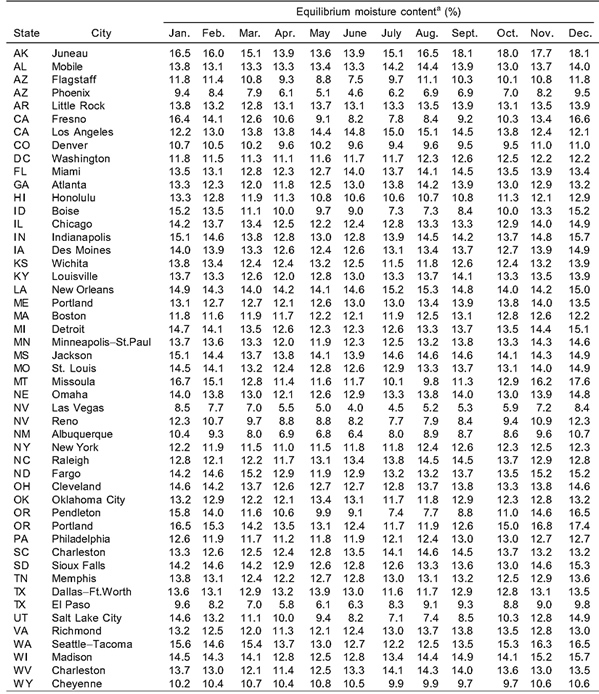

Posted in Home Page Wood Moisture Tagged Air Drying Dry-bulb Temperature Excel Spreadsheet Lumber Relative Humidity Wood Moisture Wood Products. Group 3- Slow drying hardwoods red and white oak rock elm This chart is based on 010kWh electricity 10C 50F outside temperature building sized for the load size listed and as a separate building while also assuming electric pre-heat. Hardwoods take more time to dry because theyre denser than a softwood.

Air-drying cedar wood takes anywhere from three to twelve months. Air-drying times can be affected by the rate the water moves through the wood the relative humidity in the surrounding air and the temperature. Drying times can depend on how warm it is plus the humidity you experience.

Minimum air drying times listed are for lumber stacked for drying in southern locations in the spring or early summer and the maximum times are for lumber stacked in northern locations in the fall or early winter. Each species of wood will burn and dry differently because each has its own density and moisture content. For example the time range for air drying northern red oak is 70 to 200 days.

Most wood is seasoned within 6 9 months but there are so many variables that affect the time it takes to dry firewood. Calculating the Equilibrium Moisture Content. Made from published charts James 1988.

Download the Article. In the majority of cases the drying schedules are from the world literature with emphasis on US Canadian and British publications. Thats pretty much true -- it can take nine months to a year for some firewood to properly dry or cure Drying time varies with the cut.

CAPACITY CHART 16 How Profitable Are Nyle Machines. Although some meters have scales that go up to 120 the. Generally the oil-base filler will dry on the surface layer in 5 to 10 minutes.

Kiln or heat drying significantly speeds up the drying process and depending on the moisture content it can be as little as 10 hours. This article is an attempt to consolidate that. If a meter reading increases as the electrodes are being driven in then the moisture gradient is.

Internal overpressure resaturation of the end piece thermal conduction along the thickness and end piece close to the wet. Many of these numbers are from other sources books internet. So as you can see properly stacking firewood and allowing air drying must occur before it is burned in a wood stove.

Sortable PLUS drying times what more can a wood burner need from a firewood chart. Lumbers dry weight of three pounds per board foot is a ratio of 23so the lumber has a moisture content of 23 or 67.