Press Brake Tonnage Chart

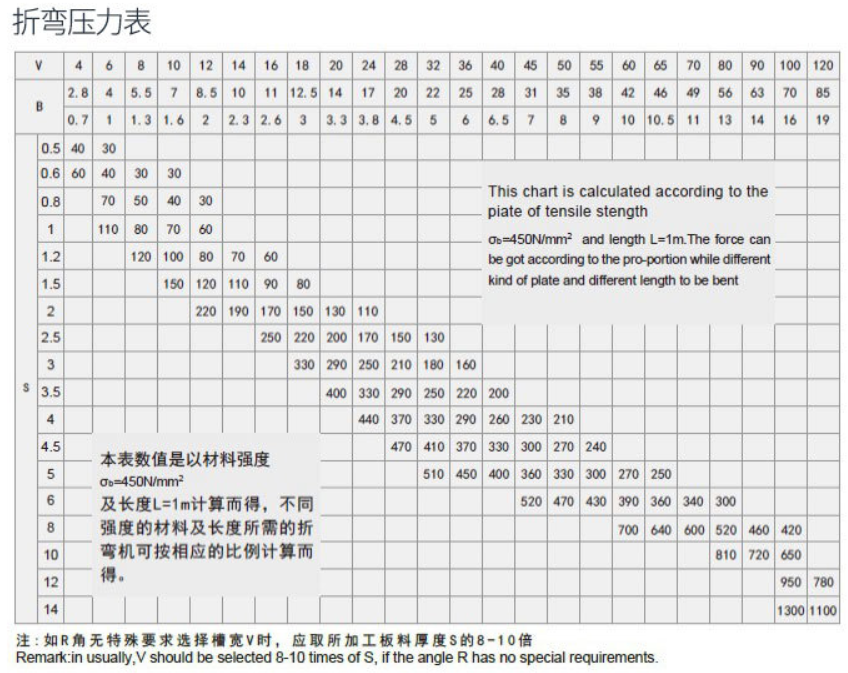

Generally slot width VS8.

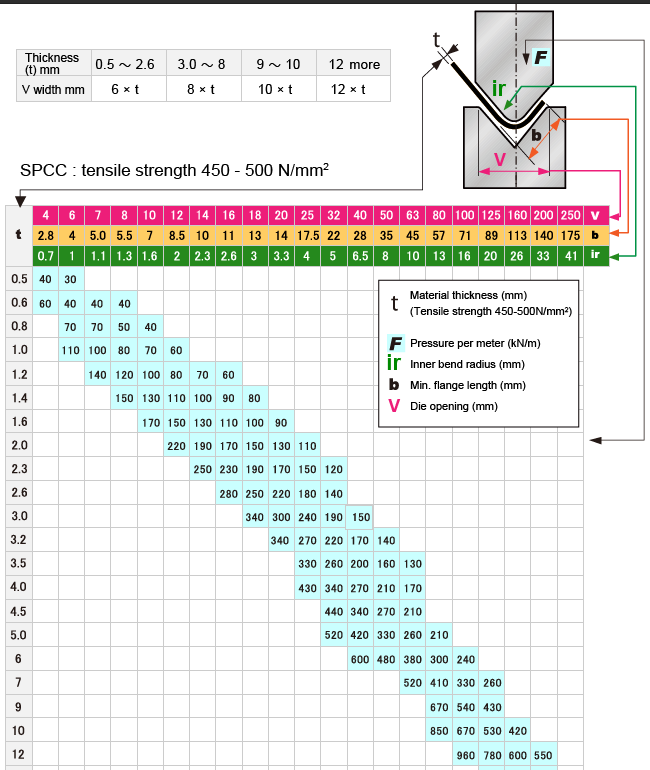

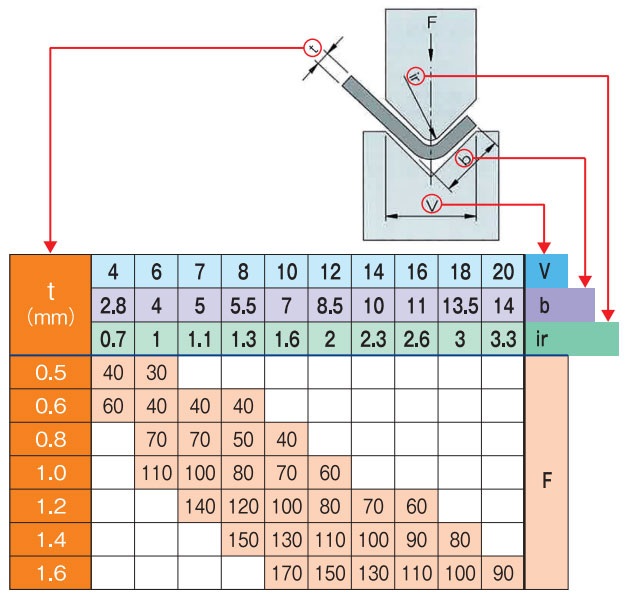

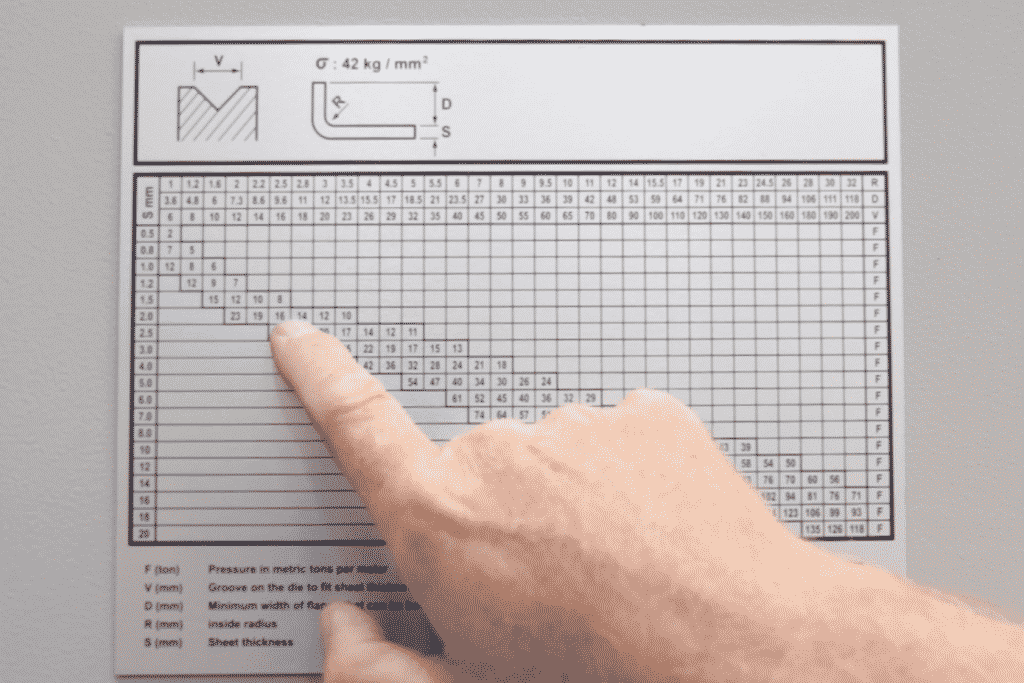

Press brake tonnage chart. Another press brake tonnage calculation formula is. S4mm L3000mm V32mm Check the table P330kN the total tonnage is 330kN x 3m 990kN 100Ton. All bending tools have limits of force to be used.

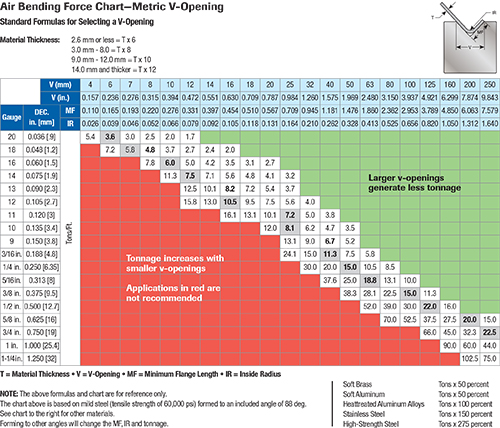

For many years I have used the following formula to calculate the forming force that would be required to complete a bend. Soft Aluminum 50 of pressure shown. About Ashmores Press Brake Tooling Limited.

575 Material thickness2Die opening12. Usually we can get a good bending effect based on this ratio. We offer Press Brake Tooling to suit all models of press brake.

With an eight-to-one die ratio the inside radius of a right angle bend is approximately equal to the thickness of the metal. If bend the 4mm sheet in 3 meters then the tonnage should be 3303990KN which equals to 101 Ton. Now we know that for bending the sheet metal with 4mm thickness and 1m length the required tonnage is 330KN.

You should choose at least 100ton press brake. Ashmores are the UKs longest established Press Brake Tool manufacturer established in 1919. Regarding how to use the chart you can refer to this post.

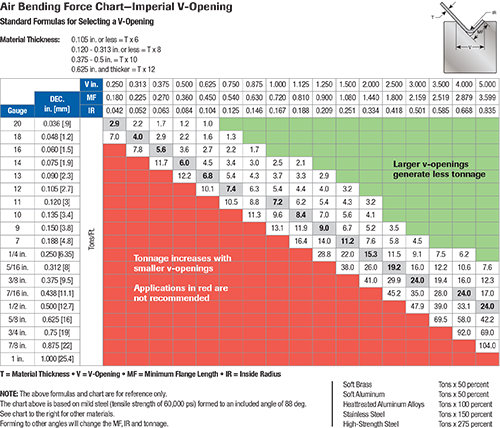

Plate thickness S4mm width L3m σb450Nmm². Now all different kinds press brake machines are designed to bend to a certain proportion of force capacity. 26 rows Press Brake Tonnage Chart Approximate pressure in Tons per Linear Foot Required to Make 90 Air.

Obtained tonnage by the press brake bending tooling compare to the necessary force. The Press brake Tonnage Calculator can be used to estimate the required tonnage to air bend a part. The knowledge gained from this experience has confirmed our conviction that the use of superior tooling ensures optimum performance each.

Tensile strength Mpa For example. Please review with your local CINCINNATI Sales Engineer when using calculator to size a new machine. In general we have two ways to calculate the press brake tonnage one is use press brake tonnage chart and another is to use formula.

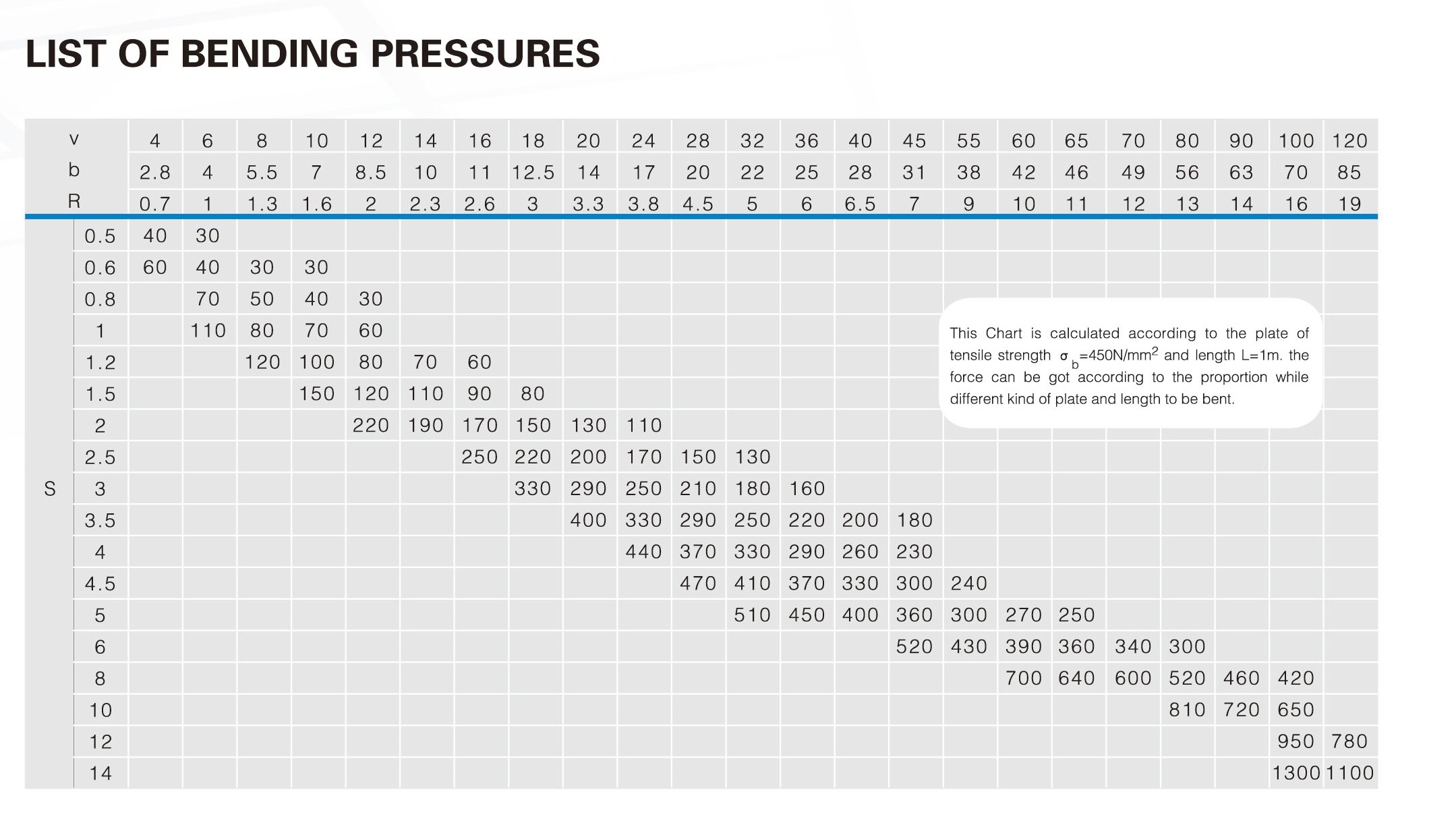

MODELS B212 B412 B512 B224 B424 B624 B824 B1024 PM242 PM442 PM642 PM842 PM1042. The following press brake tonnage chart can help you get the required bending force easily. In order to calculate that number you can use formulas or refer to manufacturer tonnage charts.

Of workpiece bending 12 plate and more. The actual tonnage may vary from this calculation due to several factors such as the friction of the material on the die thickness variations of the material and actual tensile strength. However this ratio is not fixed.

Punch with radius equal to. Forming tonnage per inch. From there the answer would be factored for material type length of bend and method of forming.

The unit of 330 is KN. Plate thickness S 4mm width L 3m σb 450Nmm2 Generally slot width VS8 Therefore P1 424504234 89585 KN 96 Ton. CINCINNATI Press Brake Capacities booklet PT-50691 Bend Allowance Chart.

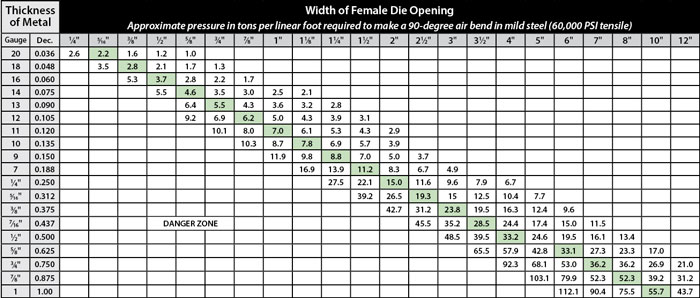

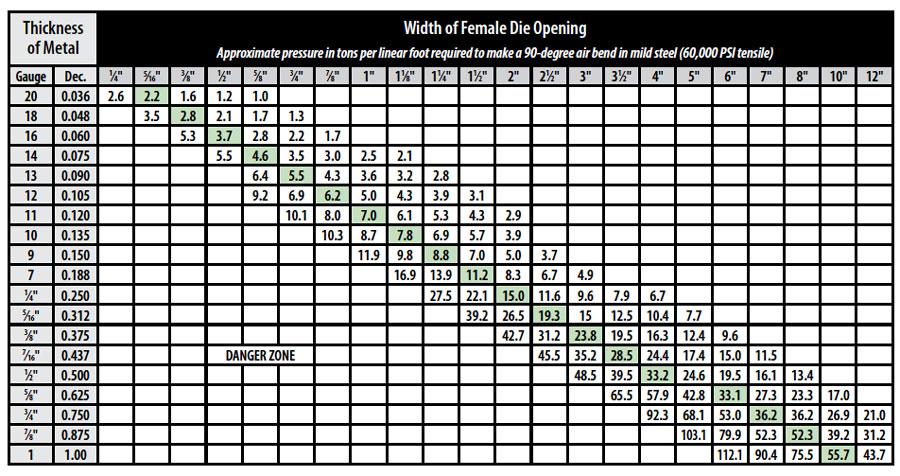

Tonnage 12 90 PSI 24 90 PSI 42 100 PSI. When using material over 12 it is usual practice to have die opening 10 times the metal thickness. Force to Air-Bend Mild Steel 60000 PSI US.

Bending force KN S. The tonnage required depends on the thickness and length of the plates you will use as well as the metal that will be bent. Electro-Hydraulic Servo Press Brake Operation Manual.

Of workpiece All Dimensions in inches 316 Tonnage requirements for coining are 3 to 5 times Greater than when air bending. Bending pressures for other metals are. The bending forces for mild steel are shown on the chart below.

The first factor to consider in purchasing a press brake is the bending force or tonnage required. Model B212 CNC Back Gauge Model PM642 Model B424 with punching units. The range includes tools to suit all Euro style machines Trumpf Wila Bystronic LVD and many more.

From the press brake tonnage chart the force capacity is designed according to the ratio of bottom die and sheet or plate thickness. It means that you can verify the max. TONNAGE CHART MATERIAL THICKNESS WIDTH OF FEMALE VEE DIE OPENING Approximate tons per lineal foot of forming based on Air Bending 90 bend in mild steel.

You can use this calculator to calculate necessary tonnage for press brake to perform the bending of necessary part. The shaded figures represent ideal conditions for right angle bending. Standard Press Brake Dies.

Data of V R B. Press Brake Dies Toolings. Consideration in the selection of a press brake.

The Ultimate Guide 2021 Updated Press Brake. It is recommended that the press have 20 excess capacity. Here we come to the conclusion.

Perfection Machine Tool Works offers the best press brake tonnage chart. Plate thickness mm L. Air Bending Tonnage Charts 90 Press Brake Tooling AMADA Quality Tooling AMADA has been the leader in the production of Precision Press Brakes for over 40 years and we have installed more than 80000 machines worldwide.

Soft brass 50 of pressure shown. Therefore P650 4² 348975 KN 995 Ton The result is very close to the data in the bending force chart. A Overall Width 40 64 76 36 60 84 108 132 38 62 86 110 134.

Storage Rack Corrugated Panels. PRESS BRAKE AIR-BENDING TONNAGE GUIDE Force to Air-Bend Mild Steel 60000 PSI F US. As you can see method 1 to calculate the press brake tonnage is based on the mild steel material.

The tonnage calculator is for 20ga to 3 material bent over a vee die in the range of 5 to 19 times the material thickness. By using the Formula the tonnage should be P 650 x 4 x 4x 3 8 x 4 100 Ton.