Mig Welder Settings Chart

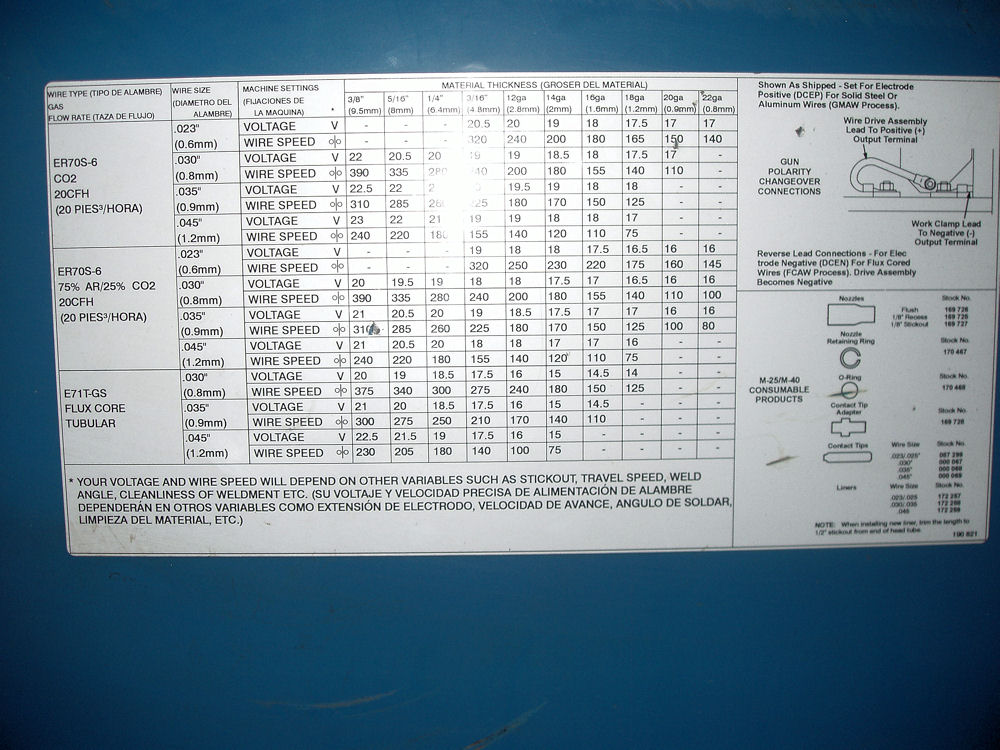

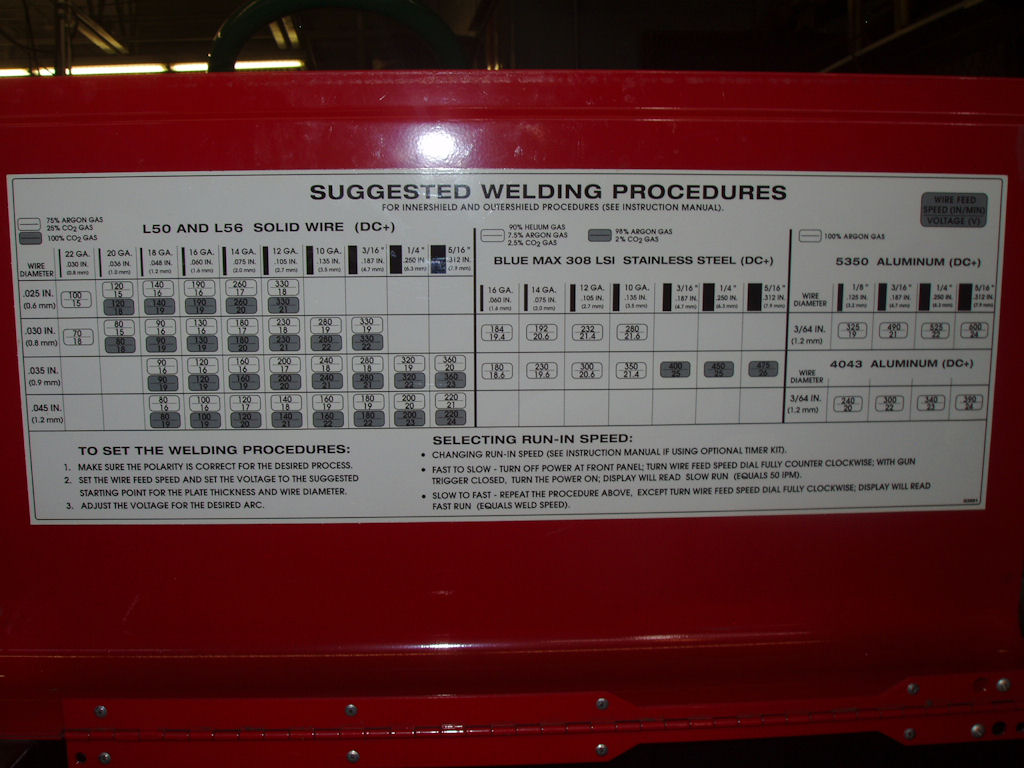

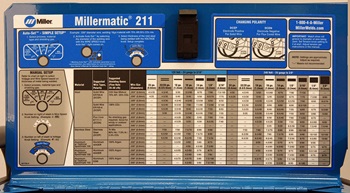

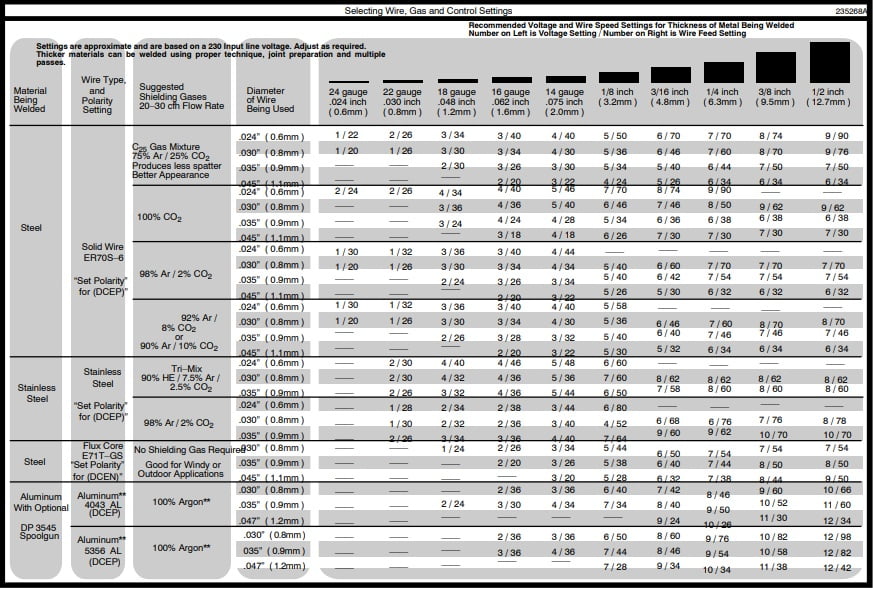

There are many MIG setting charts available from manufacturers that all vary.

Mig welder settings chart. And youll need to weld multiple passes for 14 inch and 516 inch thick mild steel on your Lincoln 140. It will contain recommended settings. Sip 150 Mig Welder Settings Manual.

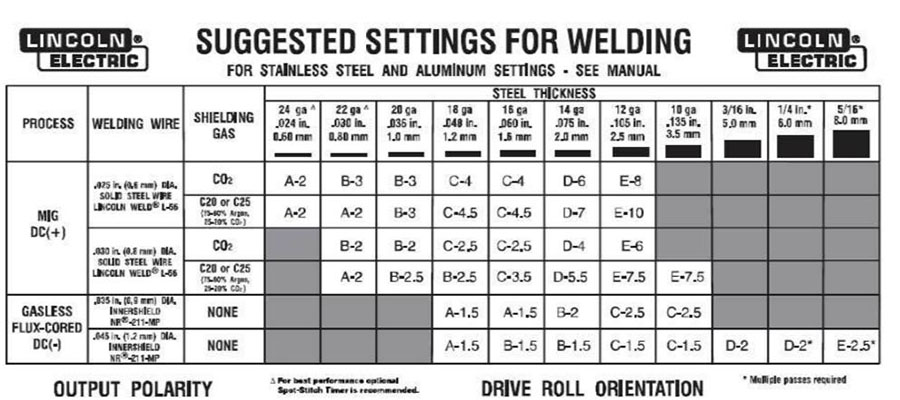

SIP T166 MIG Welder. Previous Post Fishing Chart For Today. To start the pictures above and below are the manufacturers recommended Lincoln Welders and Miller Welding Equipment voltage wire feed speed settings and gas recommendations.

MIGMAG welding 6 TIG welding 10 Plasma welding 17 Welding sheet 18 Welding plate 20 Welding pipes 22 Defects in welds 24 The right gas. Posted on October 18 2020 by Eva. MIGMAG welding 30 Flux cored electrodes 33 TIG welding 34 Oxy-fuel gas cutting 37 Plasma cutting 44 Safety always 46 Conversion data inside back cover Air Products.

MIG Welding Electrode Wire Selection Guide Chart MIG Welding Electrode Selection Chart Lincoln MIG Welding Electrode and Gas Selection Chart Settings Welding Carbon Steels and Mild Steels. There might be variations with the settings depending on the manufacturer. MIGMAG welding 26 TIG welding 29 Welding data.

If youre confused about which MIG welding polarity settings you should be using for flux core wire and for solid wire. Miller Mig Welder 252 Settings Chart. MIG settings for welding different thickness mild steel.

The parameterssettings of the flux core welding wires for vertical welding positions are quite different than that of the usual positions. Silicon Bronze Mig Brazing Basics Millerwelds. Carbon Steel AMPS Chart Stainless Steel and Aluminium AMPS Chart.

Hey Panda Go to the weld wire Manufacturers website. Next Post Penn And Teller Theater Seating Chart. Start off the process of selecting wire size by looking at the welding parameter chart that should be located on the welding machine itself.

Browse suggested weld parameter settings for Stick Welding TIG Welding MIG Solid-Wire Welding and MIG Flux-Core Welding. These two MIG welders are ideal hobby welders and can weld using gas or in gasless modeThe SIP Migmate T166 can weld from 07 to 62mm. Youll see youll need flux core wire.

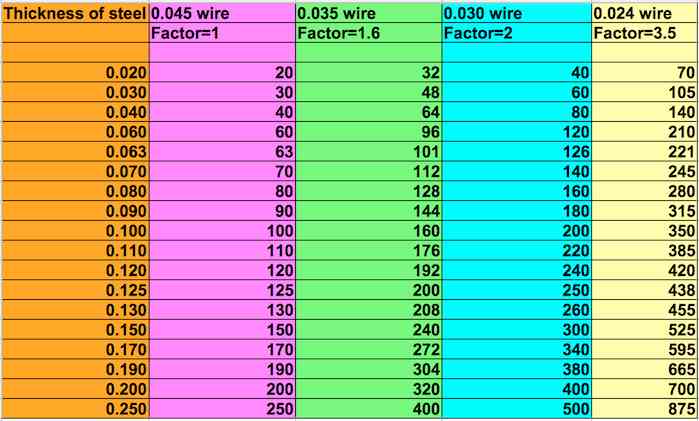

As it is synergistic controlled when we select the voltage the speed of wire and ampere will be automatically changed base on welder data inside the welding machine CPU. Hence a chart has been plotted right below mentioning the wire sizes and their respective flux core vertical up settings accordingly. Mig Welder Settings Chart.

The above picture shows you the bottom of the Lincoln 140 MIG welder settings chart. These are considered non-essential. Your final step for setting up a MIG welder for aluminum involves tweaking the non-essential variables.

Mig welder settings explained with chart weld guru a mig welding s to metal thickness chart mastermind mig welding settings explained wire sd vole chart miller mig welding calculator 086446 how to flux core weld by 2021. 8 rows To calculate MIG welding wire feed speed you need to multiply the necessary current of your. 22 rows r-tech mig180 mig welder welding settings carbon steel - 06mm wire diameter info joint.

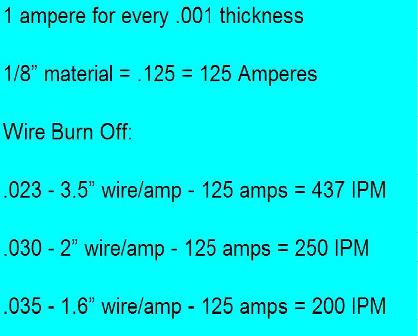

Heres a settings chart I put together that is a general guide to get you started remember this is just a guide. Mig welding settings limited time offer millermatic 252 mig welder 208 230 volt practical hinist largest 252 mig welder 200 volt s at 28 most versital welder. Always test your settings on a scrap piece of metal.

C25 25 Carbon Dioxide and 75 Argon or 100 Co2. YesWelder MIG-205DS Welder Setting Chart Here is a welding chart for YesWelder MIG-205DS Welder. Silicon Bronze Mig Brazing Basics Millerwelds.

This chart will tell you the MIG wire types that the machine and weld gun are compatible with. MIG Settings Chart based on Wire Selection Get the full-size printable PDF here. From your previous posts I think you were using 0035 wire short circuit transfer not sure which gas you are using.

It shows you the thickest your Lincoln 140 will weld. Here is a chart that summarizes the MIG welding amps according to the three most common types of metal and their thickness.