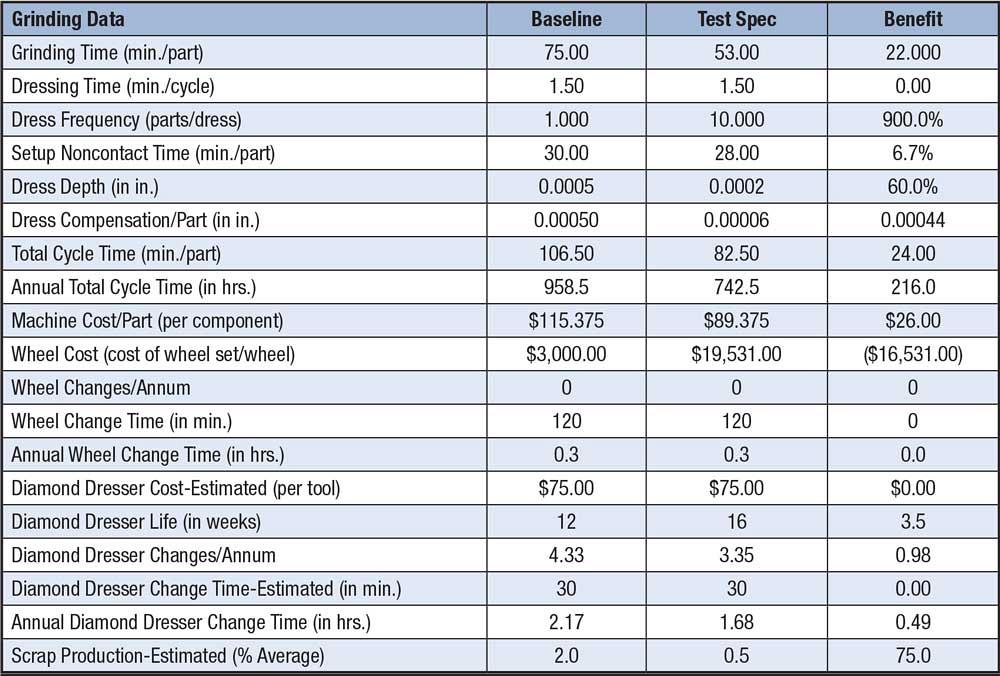

Grinding Wheel Selection Chart

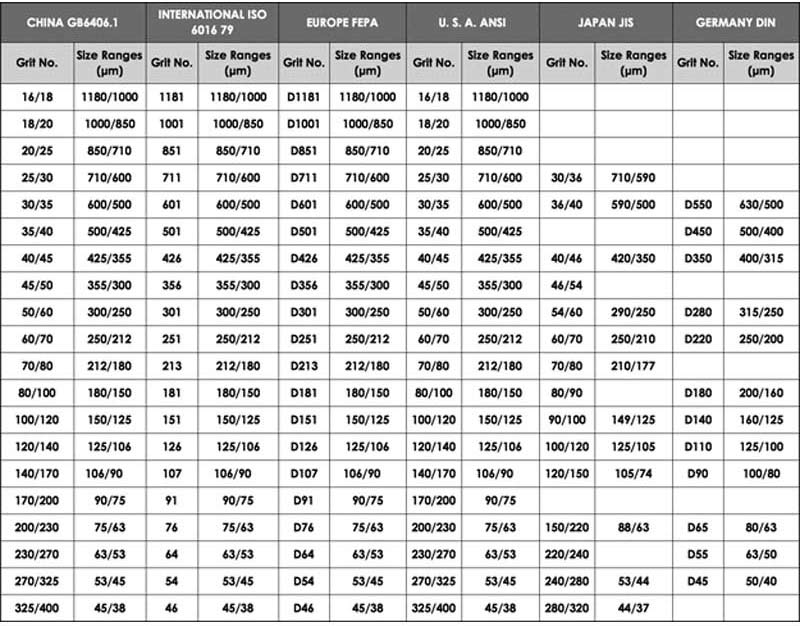

Grinding wheel grit chart Grit size and surface finish.

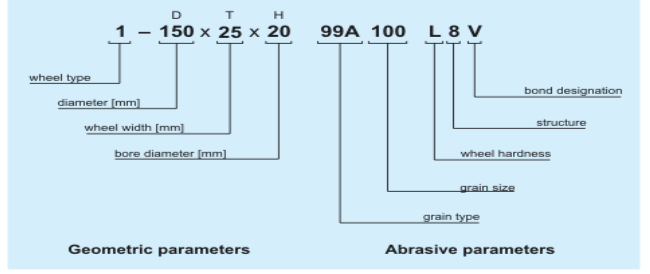

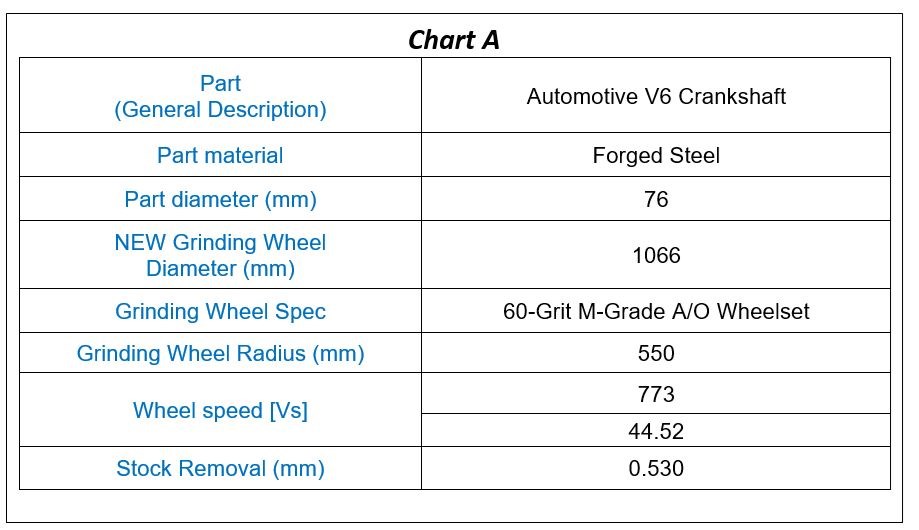

Grinding wheel selection chart. Microcrystalline fused alumina grinding wheel. Ws Ps x Z E E 600 x 30 45 4000 4000 x 4 Ps 533 RPM 30 Ws x E Ps Z. Al2O3 wheel is preferred for most of the applications.

For grinding titanium SiC wheel is used and for grinding carbide and ceramic materials diamond wheel is. It is suitable for grinding stainless steel high vanadium high-speed steel and other workpieces with high toughness high hardness and easily deformed burns. Type of Grinding Machine Variable Factors 1.

I assumed that you already have a brief idea about Grinding Machine. Resinoid Bond These bonds are prepared by mixing abrasives with synthetic resins like backelite and redmanol and other compounds. X E Z 1.

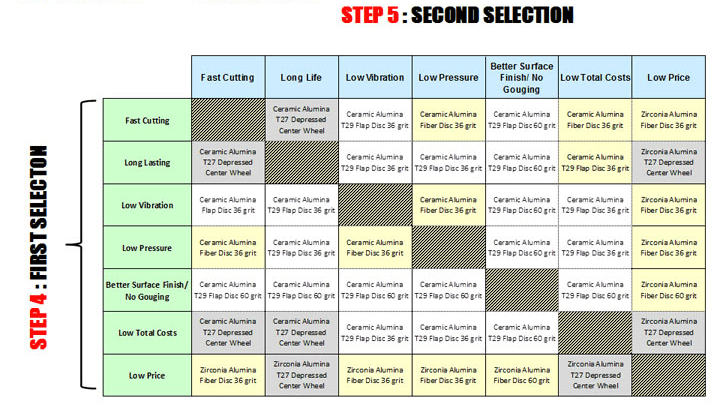

Characteristics of the Grinding Wheel. Soft wheels are applied during grinding work pieces where alarge amount of heat emission is. Selection of Grinding Wheels for Thread Grinding and Tool Sharpening.

Diameter of grinding wheel x Thickness of grinding wheel x size of arbor hole -. Area of Contact 4. There are nine main factors to be considered when selecting a grinding wheel for any application.

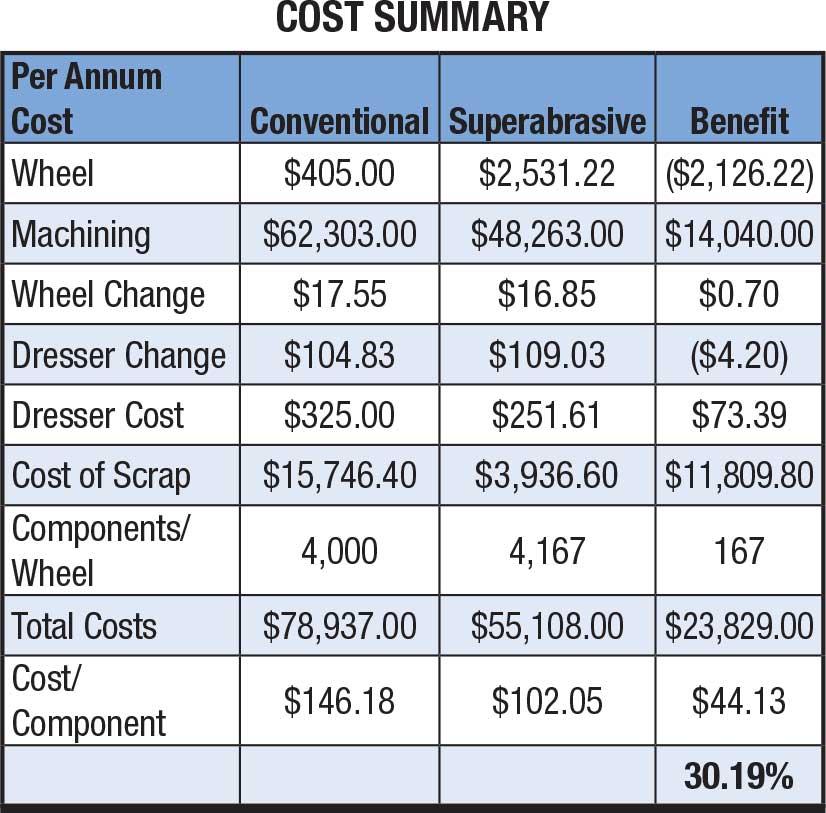

Page 4 Angle Grinders Finishing Polishing Suitable for Providing a high gloss finish to complete a project. Increasingly stringent requirements for gears result in tighter tolerances higher profile accuracy and improved surface finish. Explore surface grinding wheel specifications types and a selection guide.

Non-Reinforced Resin Bond Conversion Table. Toolgal Diamond Wheels is an experienced manufacturer of High Quality Diamond and Borazon grinding wheels. Selection of grinding wheels is.

Metal bond grinding wheels. Ni Hard Rolls. Bench Wheels Page 9 Die Grinders Angle Grinders Cutting Suitable for Accurate and fast cutting of materials.

If you not learned yet. What stock needs to be removed from the material. Material to be ground 2.

Industrial Applications of Grinding Wheel. Personal Factors 11. It is suitable for grinding stainless bearing steel and special ductile iron etc.

The particular abrasive used in a wheel is chosen based on the way it. Selection of Grinding Wheels for Thread Grinding and Tool Sharpening. More questions about grit selection ASK FOR HELP.

Posted on March 26. Grinding Suitable for The removal of welds and burrs. The factors influencing the type of abrasive for thread grinding wheels are the material of workpiece its hardness pitch and profile of the threads.

Bushings Connecting Rods. Materials used in Grinding Wheels. Work out the shape of the material and the surface finish or finishes that are required.

Grinding Wheels for hard metal and steel tools industry. Surface Grinding Wheel Chart. What material will you be grinding and how hard is it.

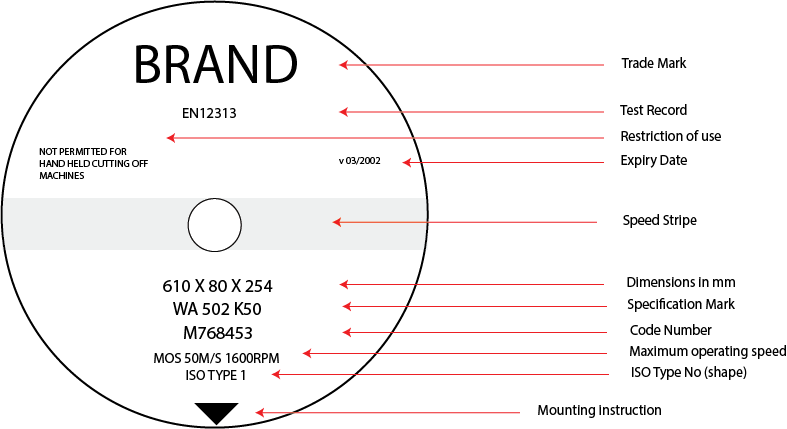

12Diameter x 2Thickness x 1-14Arbor Hole. Guide about Grinding Wheels Types Material Specifications. Selecting the right grinding wheel.

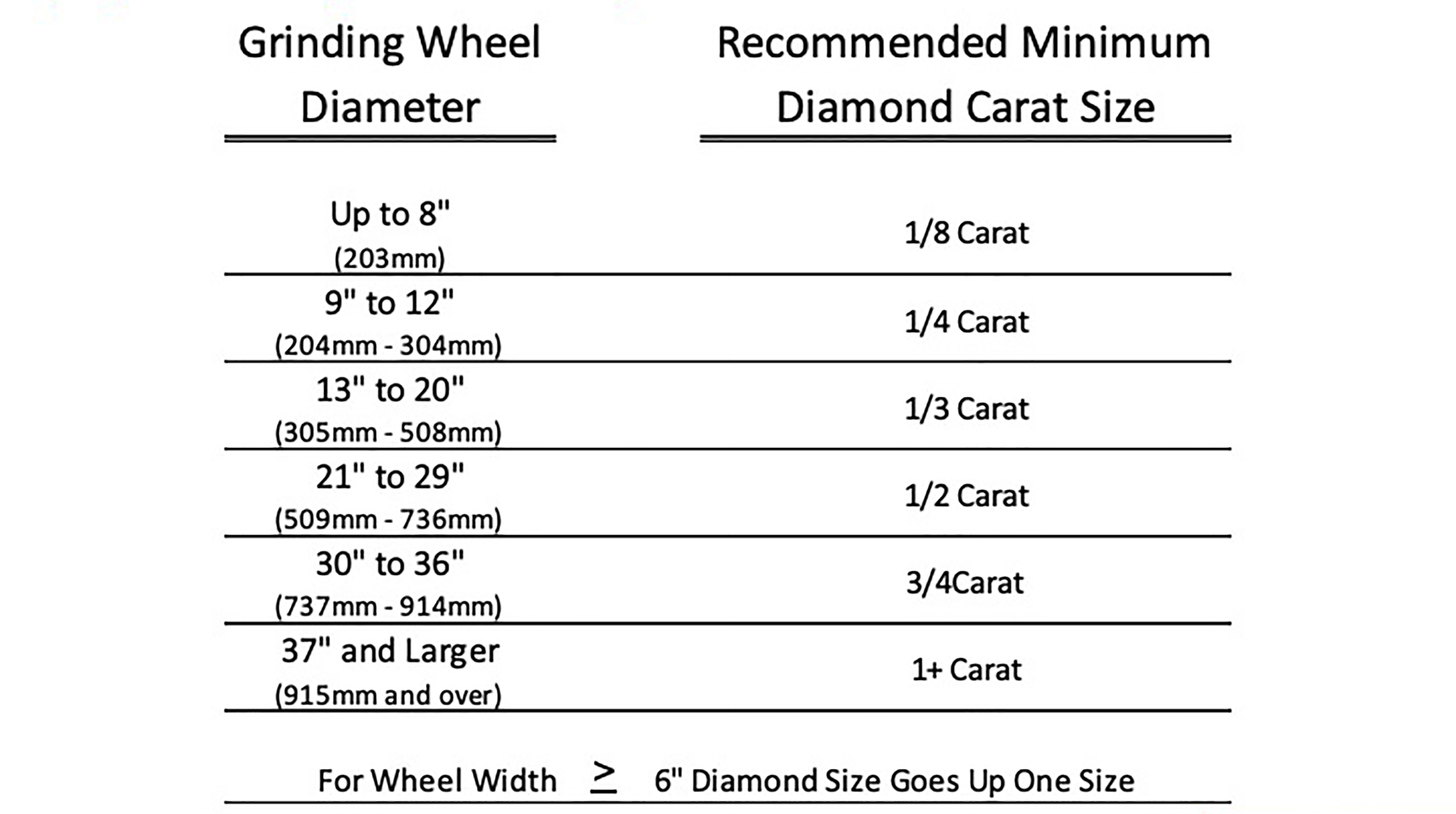

This bond is denoted by Ein specifications. Truing Dressing Guide61 6 COMPANY PROFILE Toolgal Diamond Wheels is a division of the Toolgal Group. Our engineers can assess your application needs and work with you to develop both the product.

Complementing the Master branded grinding wheel selection is the comprehensive range of dressing tools and auxiliary equipment. Gages Monel Metals. The choice of abrasive is key in the production of high quality gears.

Condition of the Machine 4. Grinding wheels having shellac bond are recommended for cool cutting on hardened steel and thin sections finishing of chilled iron cast iron steel rolls hardened steel cams and aluminium pistons. For grinding titanium SiC wheel is used and for grinding carbide and.

The percentages of grain and bond and their spacing in the wheel determine the wheels structure. Gf01 Grinding Wheels Information Disco Corporation. Monocrystalline fused alumina grinding wheel.

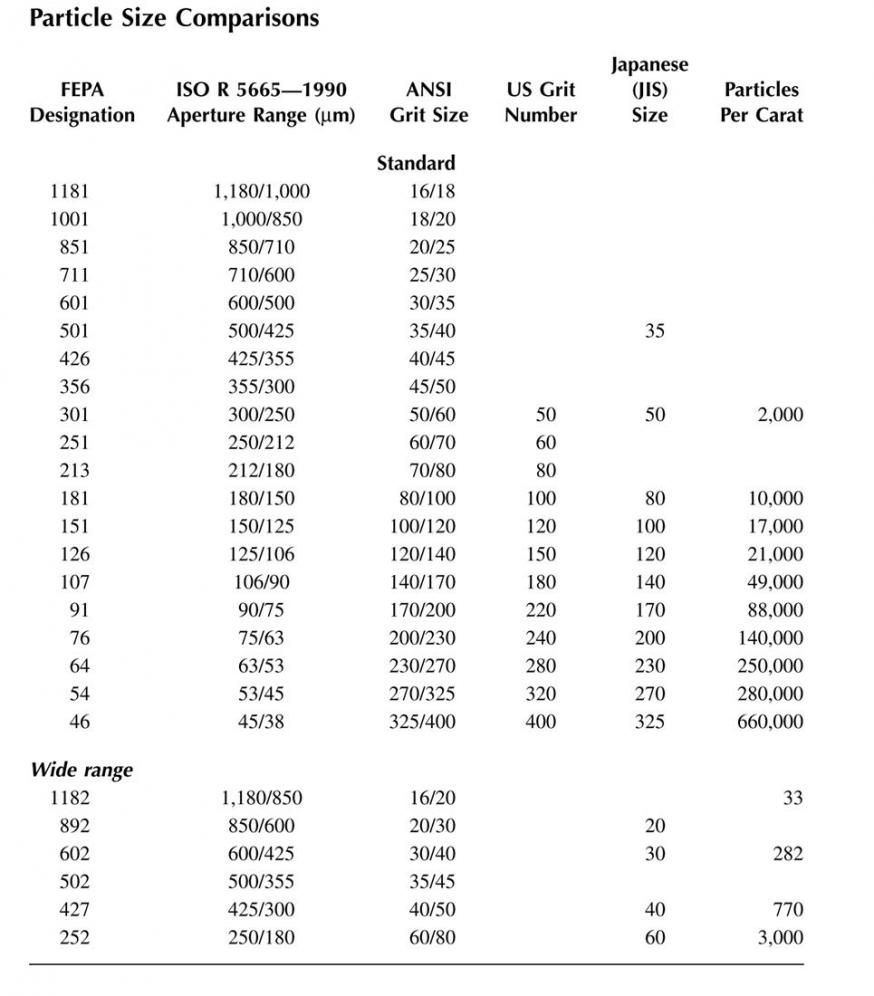

Surface grinding wheels and segments norton abrasives s technical doentation brochure gf01 grinding wheels information disco corporation thrufeed centerless od grinding parameters and. Master branded grinding wheels are manufactured to EN 12413 and provide consistently high quality under ISO 9001. Grit chart of grinding wheels Brian Zhao 2019-12-25T0925090800.

Reinforced Resin Bond Conversion Table. Toolgal supplies the wheels for several applications mainly. The factors influencing the type of abrasive for thread grinding wheels are the material of workpiece its hardness pitch and profile of the threads.

As my previous article of Grinding Machine I told grinding is an important operation in manufacturing industry to get a final product so for that we need to know about the grinding wheel and its properties so that we easily choose a right wheel for the right material. How is the grinding wheel produced. Al 2 O 3 wheel is preferred for most of the applications.

Page 27 Orbital Sanders Die Grinders COARSE GRINDING FINE FINISHING. Grinding Wheel in Industry. We will reference the AA Abrasives 60397 - 12x2x1-14 Pedestal Grinding Wheel T-1 Vitrified A36 - from our Vitrified Bonded Grinding Wheel Series.

Selection of Grinding Wheels Selection of grinding wheel mainly depends upon Constant Factors 1. Grinding wheels and other bonded abrasives have two major components-the abrasive grains that do the actual cutting and the bond that holds the grains together and supports them while they cut. Wheel Selection Inter Diament Grinding Wheels.

Hindustan Abrasives leading Surface Grinding Wheel Manufacturer in India produces Surface flat grinder wheels for a precision finish.